Production

200 years of innovation, precision, and fortitude perfecting man's oldest tool.

The WÜSTHOF Way

Made in Solingen

Unlike many knife makers, in over 200 years of history, we have not succumbed to the temptation of manufacturing our forged knives outside of our hometown of Solingen, Germany. There is a simple reason for this: we value the heritage and identity of a place known for centuries as "The City of Blades." We believe that quality knives can only be made where state-of-the-art manufacturing technology meets traditional craftsmanship.

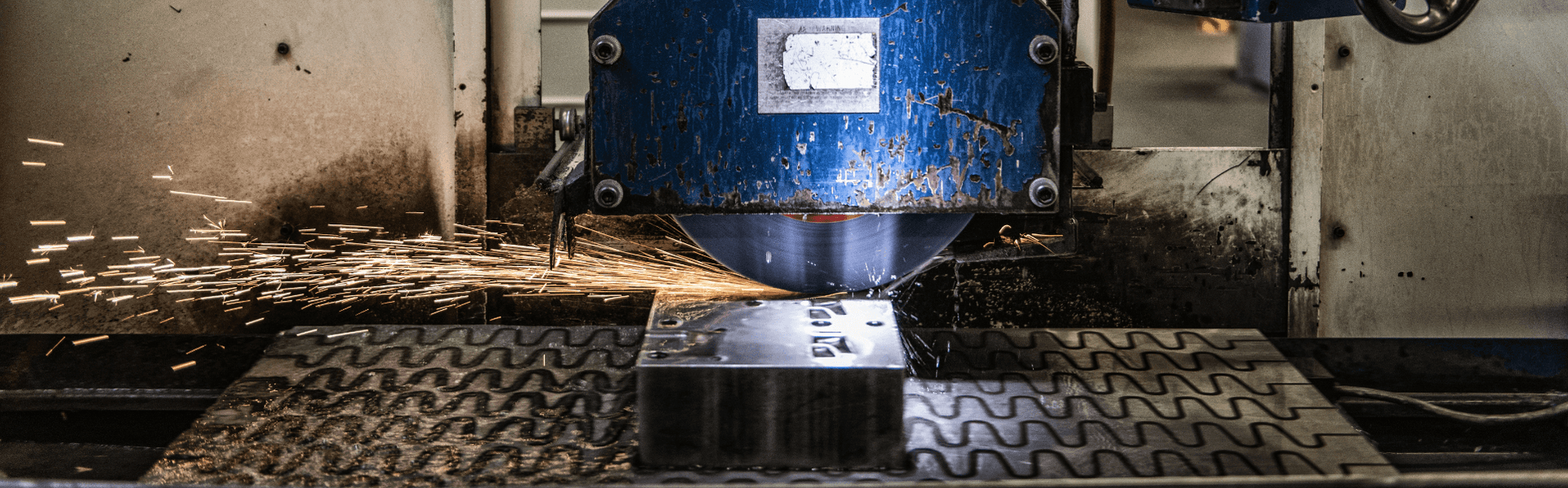

54 steps in the WÜSTHOF knife production process

It takes approximately 54 manufacturing steps to turn a piece of WÜSTHOF steel – a special mixture of chrome, vanadium, molybdenum, and stainless steel – into a quality knife. When it comes to exceptionally heavy lifting or millimeter-precise work, we use the latest robotics and lasers. When intuition, experienced artisanship, and a seasoned eye are required, we rely on our expert employees to make our premium knives truly exceptional, as no tool is more sensitive and discerning than the human hand and eye. We produce 1.7 million knives per year, and every WÜSTHOF knife has passed through the hands of a trained specialist.

WÜSTHOF Steel

We use a special steel for knife production. It's durable, corrosion resistant, easy to sharpen, and significantly reduces wear on the blade due the unique hardness of the metal. Our laser-assisted sharpening process means each knife has an impeccable slicing performance from the get-go.

Our formula for optimal sharpness: X50 Cr MoV 15

Stainless Steel

The basic material of our knives

Carbon Content

The 0.5% carbon content is important for both the hardness and the sharpness of the knife

Chrome

The additional alloy ensures a particularly high rust resistance in the finished blades

Molybdenum

An alloying element that increases the strength and corrosion resistance of our blades

Vanadium

Increases strength and toughness to significantly reduce wear

Chromium Content

An amount of 15 %